production methods Notes

In the world of business and operations, understanding production methods is key to optimizing processes and improving efficiency. Whether you’re an IBDP student aiming to ace your Business & Management exams or simply looking to enhance your knowledge, mastering production methods is essential. These methods help businesses streamline their operations, reduce costs, and meet customer demands efficiently. This blog covers crucial concepts, strategies, and techniques to give you a comprehensive understanding of production methods, ensuring you’re well-prepared for both exams and real-world applications.

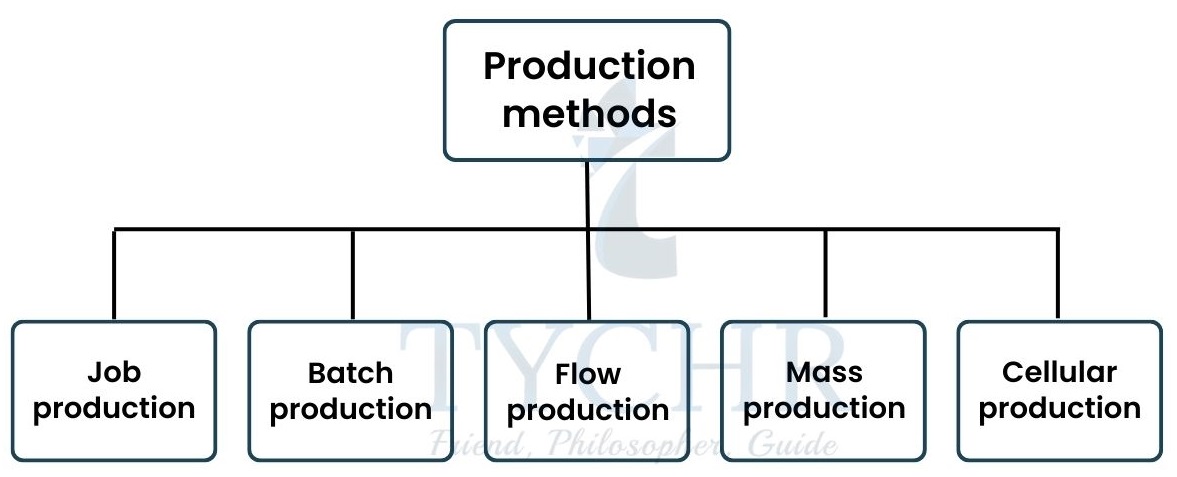

Production methods

Job Production

- This production method is used for the production of one-off items that are designed/tailored from top to toe in order to meet the specific requirements of the customers.

- Examples of few products produced with this method of production are travel or tour packages, wedding dress or ring, furniture for the house, etc.

Advantages of job production | Disadvantages of job production |

High quality and unique products are produced in order to meet the customer’s needs. | It is a time consuming production method. |

Workers are highly motivated to produce the goods/services perfectly . | It is a very expensive production method .The unit costs are high because skilled labourers are employed to produce the tailor-made products. |

Flexibility -Changes can be made during the course of production as per the customer’s request. | The organisation is not able to reap the benefits of economies of scale because each product is specifically designed. |

Batch Production

- Identical products are produced in a batch.

- This method of production is used by the business organizations that produce a wide range of products.

- In a particular batch, all the products undergo the same process of production.

- For example – Jewelry manufacturing companies such as Tiffany & Co. produce a wide range of jewelleries and ornaments in different batches.

Advantages of batch production | Disadvantages of batch production |

|

|

|

|

|

|

Flow Production

- Standardized/homogeneous products are manufactured in large quantities.

- This is a capital-intensive method of production where the workers are primarily employed to control the functioning of automated machines.

- All the products undergo the same process of production.

- For instance- Amul Indian Dairy co-operative society manufactures the delicious Amul butter with the flow production method.

Mass Production

- This production method is almost the same as flow production. The only difference is that the products are produced at a very large scale with the use of specialized equipment and automated systems.

- Unit cost of production are lower than in the flow production method.

- Automobiles, mobile phones, etc. are manufactured with the use of mass production methods.

Advantages of mass and flow production | Disadvantages of mass and flow production |

The firm gets the benefit of economies of scale since the costs are spread over high volumes of output.This reduces the average costs of the production. | Workers’ motivation level is reduced due to the monotonous nature of tasks in this production process. |

Production efficiency is high due to the use of capital intensive technique of production. | Inflexibility- The design or the composition of the product can hardly be altered once the production process starts. |

Labour costs are relatively low since unskilled workers are employed and trained to use the machinery. | The cost of capital(set up costs, running costs and the replacement costs) is very high in these production methods. |

Cellular Production

- Cellular production method is a replacement for the conventional mass and flow production methods.

- In modern days, cellular production is used to manufacture the products that involve assembling of the component parts and are produced at a large scale. For example- Cars and laptops are produced with this method of production.

- The entire production is divided into self-contained units. Each cell uses raw materials, labor and machinery to complete a part of the final product. The complete units of work are then passed on to another cell and the process continues till all the parts are assembled into final products.

Advantages of cellular production | Disadvantages of cellular production |

The workers in each cell have autonomy in decision making. This provides them with the motivation to work in teams. | In cell production, lesser output is produced as compared to mass and flow production. Hence, the costs of production in this method are comparatively high. |

The skills and talents of workers of different cells are combined to achieve the highest level of quality and efficiency. | In cell production, people work in teams in the different cells. The probability of conflict increases if the team leader is not effective. |

How to determine which production method is appropriate?

The following factors are considered by any business organization to determine which production method would be best suited for the manufacture of their products:

- Size of the markets- The businesses that operate in large markets tend to use capital intensive techniques of production such as mass and flow production methods . On the other hand, smaller size market businesses tend to use job production methods because of the inability to make investments in the purchase of sophisticated equipment and machinery.

- Relative cost of capital and labour – The relative cost of capital and labour vary from region to region. In developing countries like India, the labour is quite cheap and hence labour intensive technique of production is used . On the other hand, in developed countries, the machinery is available at a lower cost as compared to the labour.

Hence the firms operating in these countries employ capital intensive techniques of production. - Aims and objectives of the organization- If the objective of the organisation is to maximize profits then the firm is likely to use capital intensive techniques of production to lower unit costs. But if the objective of the firm is to produce high quality distinguishing products, then they use skilled labour for production(job production). Most of the businesses that aim to grow and expand combine the different methods of production.

For example – Chumbak, a lifestyle brand that was founded in 2010 produces wide range of souvenir, decor and fashion products inspired by Indian culture. The wide range of products are produced in batches but it also uses a job production method to provide tailor-made products as per the needs of customers.

In conclusion, a solid grasp of production methods is fundamental for excelling in IBDP Business & Management. By focusing on key strategies and techniques, you can optimize business operations and drive efficiency. If you need personalized guidance and expert support, Tychr offers the best IBDP Business & Operation Management tutors to help you achieve academic success. With Tychr’s expert tutors, you can gain a deeper understanding of complex topics and boost your exam performance.